Research & Development Laboratories are the beating heart of Ricerca Chimica Group. The expertise and the knowledge, combined with a range of cutting-edge instrumentation, enable the R&D team to promptly intervene on customer’s issue, providing a suitable solution. Laboratory Staff keeps up to date by taking part in courses, international conferences, seminars and workshops every year.

The R&D Laboratory includes 4 Divisions:

Analytical Division recently armed itself with advanced instrumentation for product and water analyses, able to provide precise and exhausted answers both during routine testing and investigation of possible operational faults. The Department closely cooperates with the other Divisions to provide useful information on the study for new waste water processes, changes to existing products, long-term research on new products.

Scanning Electron Microscope equipped with Microanalysis EDS (SEM-EDS)

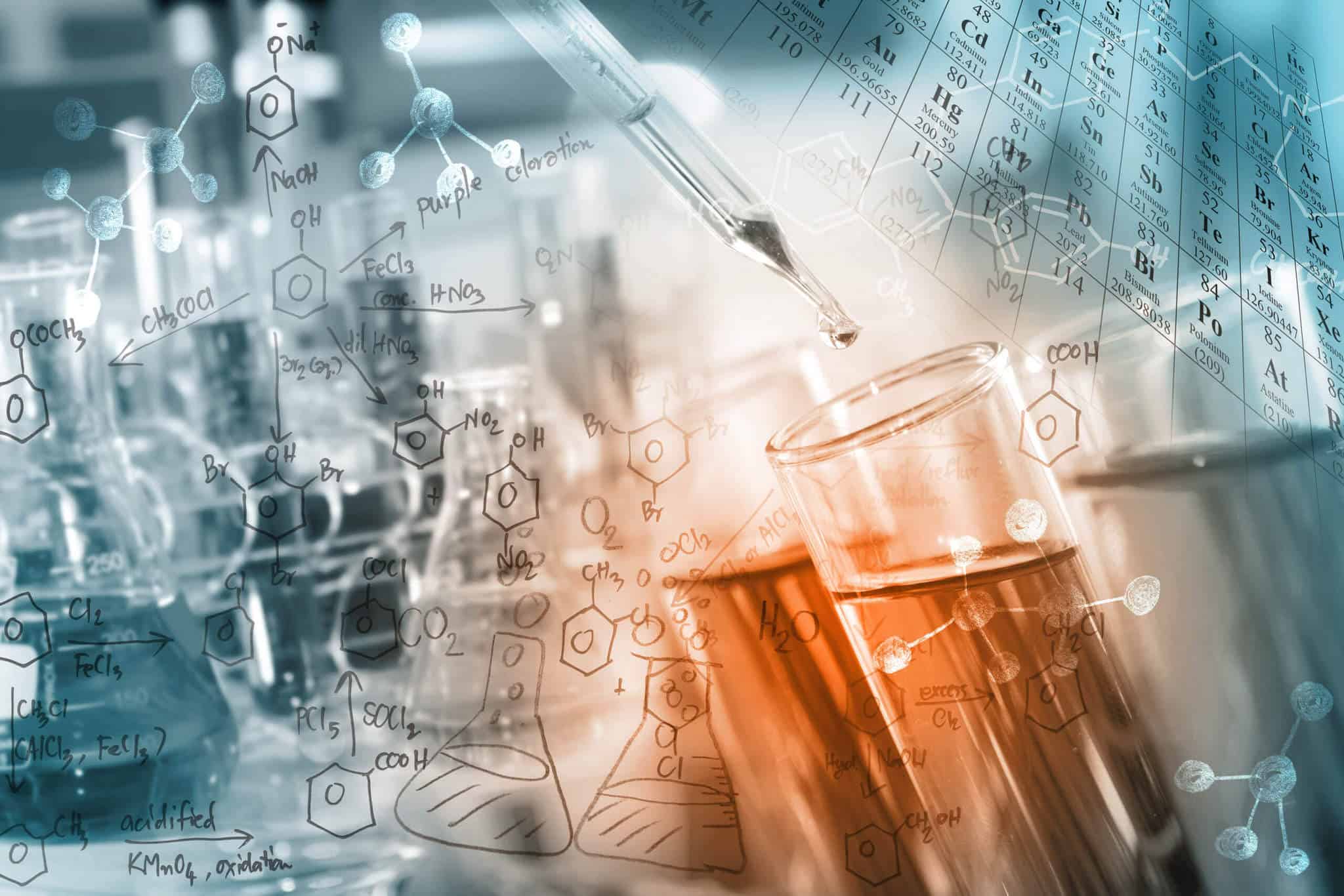

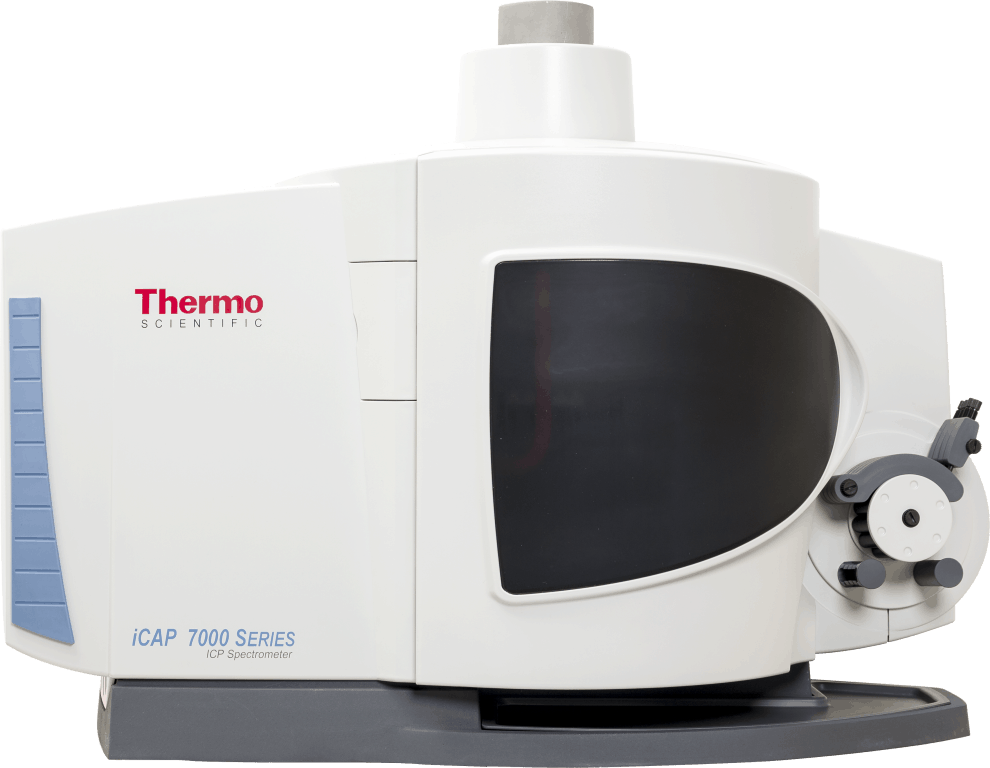

ICP-OES

ION CHROMATOGRAPHY

Thanks to resources from Analytical Division, several tests can be run:

In this way the correction is calculated from time to time reducing wastage, that means savings for customer.

The Applicative Division is dedicated to solving problems coming from Customer (such as for instance pickling or electropolishing processes on special steel alloys or on complicated metal components), entrusting the project to a researcher in charge of monitoring the whole research: analyses of the problem, proposal of different solutions resulting from Ricerca Chimica’s decades of experience, testing on samples provided by customer carried out in Laboratory. Having identified the processes closer to solution, results are described to customer for checking and a first feedback. It will then be possible to refine the process further, for getting close to the ideal solution of the problem. Laboratory is equipped with pilot plants for carrying out sampling or pre-series products.

Research and Development Division is pursuing the Study for Ricerca Chimica’s new products, aimed at following the philosophy of Cosmetics on Metals. New products are studied within conventional fields, as well as under new requirements of the market, so as to combine innovation, productivity and environmental safeguard. Conventional reagents, often very effective but hazardous to operator and environment, are replaced by less dangerous raw materials, keeping the high quality standards belonging to Ricerca Chimica. At our laboratories, new techniques are studied and applied in order to face today and tomorrow’s problems regarding pickling, polishing, water treatment.

RICERCA CHIMICA GROUP is a dynamic and varied reality actually composed by two complementary companies, owned by Maranelli family. The Group has been operating for over 30 years in the field of surface metal treatments as manufacturer of CHEMICAL PRODUCTS, ELECTROCHEMICAL EQUIPMENT, PLANT and subcontracted SPECIALIZED PROCESSING. Being an European Leader in this sector and holder of many registered patents, RICERCA CHIMICA GROUP relies on three internal RESEARCH LABORATORIES dedicated to development and improvement on technical/chemical innovative products, in compliance with environmental and work safety standards. The company has cutting-edge technologies to guarantee a saving in terms of time and energy consumption, it also offer Tailored Solutions for the treatment on Stainless Steel, Titanium, Aluminium, Copper, Nickel, Brass and Iron. The Company designs and builds Plants for Electropolishing, Electropickling, Multi-material Passivation, Anodizing, Etching, Electropolishing on Titanium as well as Waste Water Treatment Systems for the treatment of all provided chemistry.

Thanks to these means and to the remarkable experience of Trials and Corrosion Testing Division, manifold tests can be run:

Measurement of weight and thickness loss on the treated pieces, with high accuracy